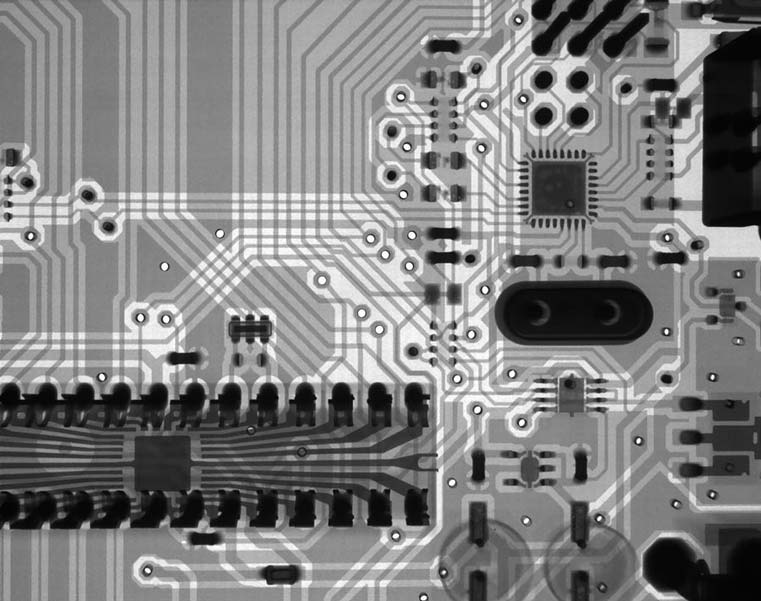

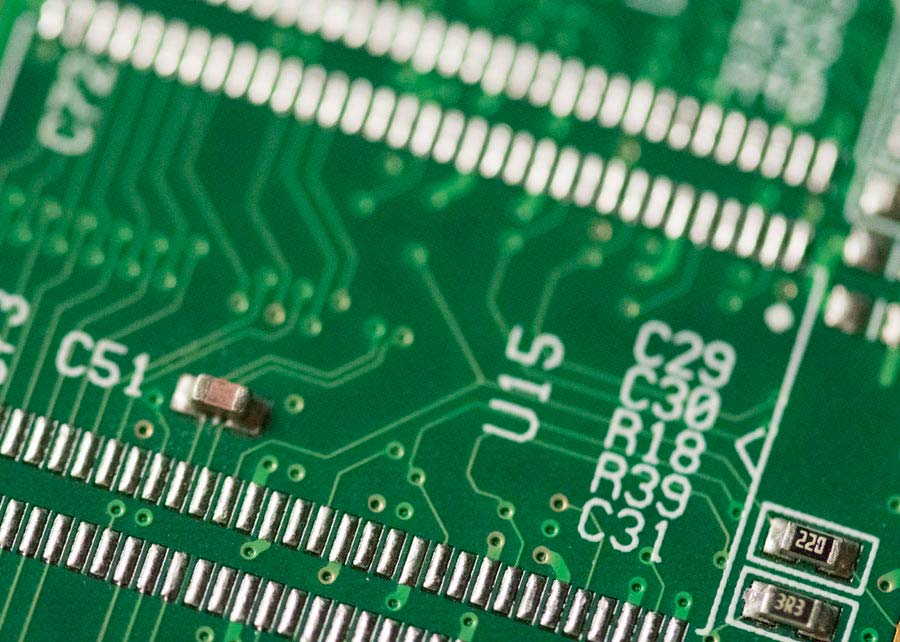

Parylenes are chemically and biologically inert and stable and

make excellent barrier materials.

Parylenes are almost completely unaffected by solvents, have low bulk permeability and

are hydrophobic. Coatings easily pass a 100hr salt-spray test.

Parylenes have excellent electrical properties: low dielectric constant and loss with

good high-frequency properties; good dielectric strength; and high bulk and surface

resistivities.

Parylenes have good thermal endurance: Parylene C performs in air without significant

loss of physical properties for 10 years at 80°C and in the absence of oxygen to

temperatures in excess of 200°C.

Parylenes are transparent and can be used to coat optical elements.

Coatings perform well as dry lubricants: static and dynamic friction coefficients are

equal and comparable to fluoropolymers with the advantage that they also have good wear

and abrasion resistance.

FDA approval of parylene-coated devices is well-documented. The coatings comply with USP Class VI Plastics requirements and are MIL-I-46058C / IPC-CC-830 (latest revision) listed (as class XY).